A Trusted UK Supplier Of ESD Control Products Since 1986

A Trusted UK Supplier Of ESD Control Products Since 1986

Bondline’s team has over 35 years of experience and knowledge of the electronics industry and extensive product range.

In this section you will find our most frequently asked questions (FAQs) and ESD glossary terms to help guide you around the topic of ESD.

For more information and any questions, please contact us.

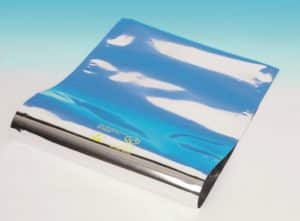

Using the correct packaging and materials not only protects your static sensitive components, but it can save you money too. If you use incorrect packaging then you could potentially cause damage to your device/component.

See our ESD bag range here.

If bags, holding static sensitive components, are to be handled outside of an EPA, they should be metalised shielding bags – a faraday cage. Metalised shielding bags can be an effective faraday cage, subject to the quality of material and physical condition.

See our metalised shielding bag range here.

Do not crease the bag as this can breakdown the integrity of the metalised shield. You should not use any bags damaged with tears and / or punctures as these can destroy the function of the faraday cage. Metalised Shielding Bags can deteriorate with use, monitoring them for effectiveness is crucial.

See our metalised shielding bag range here.

They should only be used for non-static sensitive components, e.g. Nuts, bolts, paper. These are the only acceptable ‘plastic’ bags in an EPA. They offer no effective protection against a contact ESD. Antistatic bags deteriorate with wear and time, monitoring them is very important.

Note: Ordinary plastic bags can generate and hold static charges in excess of 10,000v!

See our antistatic bag range here.

Moisture barrier bags are designed for the packaging of SMD’s protecting them from moisture and static damage. Dry devices are placed inside the moisture barrier bag and the moisture-laden is evacuated.

See our moisture barrier bag range here.

Humidity Indicator Cards (HIC’s) are used to determine when products have been exposed to moisture above recommended storage levels. They are a low-cost method of indicating humidity conditions inside a moisture barrier bag after vacuum packaging. Each Humidity Indicator Card is printed with moisture sensitive spots, which respond to various levels of humidity with a visible colour change from blue to pink. The humidity inside dry packed moisture / metallised barrier bags can be monitored by including a HIC inside. When the bag is opened, the card can be examined for proper dryness inside the bag. This indicates that the barrier bag and the desiccants are functioned correctly.

In order to constantly verify that dry packaging methods are not compromised during storage and transport of products, Humidity Indicator Cards allow users along the supply chain to monitor the packages conditions. The cards are reversible and change as conditions change in the packaging environment, allowing users to monitor the conditions of product packaging.

Humidity Indicator Cards generally range from one spot to six spot cards. Our Standard Humidity Indicator Cards and Cobalt Dichloride Free Humidity Indicator Cards are available in three spot, four spot and six spot.

There are many factors that can affect the total delivery cost, including the weight of the item(s), the location the product will be delivered to, etc.

Generally, our delivery pricing is as follows:

To discuss overseas delivery cost or if you require more information, please contact us on tel: 01793 511000 or email: sales@bondline.co.uk.

If your order has been processed it may be too late to cancel your delivery, please contact us as soon as possible. If the order has been dispatched, you can return it at your cost for a refund / credit note. If you have a specific day request for delivery we will endeavour to deliver on your requested day.

Unfortunately, this is not a service that we are able to offer at present. But if you make a request in order notes we will endeavour to deliver on this date.

Once we have received and processed your order you will be unable to change delivery address.

If there is no one to receive your parcel by courier a card will be posted through your door advising of a delivery attempt. There will be a contact telephone number on there for your local branch. You can then use this card to arrange collection from the depot or re-delivery.

We want all of our customers to be satisfied with their purchase but we also understand you may wish to return items. All products can be returned if they are in re-saleable condition and in the original packaging. Our return process is very simple. Please contact us on sales@bondline.co.uk or call 01793 511000 to discuss your return. We will give you confirmation to return for either a refund or credit note for future purchase.

Please contact us to discuss if you have a fault with our products, we may have a solution that can be resolved without returning the product.

If we believe the item is faulty, we will either repair it or replace it under our warranty terms and conditions.

We have three methods of delivery available for United Kingdom, see below for our different options.

We will deliver items based on your ‘shipping address’ requested when placing your order.

Orders totalling over £100 net are delivered free – UK Mainland. (Subject to products available to order and heavy shipments.)

We aim to deliver your goods from our warehouse within our normal dispatch time of 2-3 working days since placing your order (excluding weekends and UK public holidays). However, occasionally this can extend to 5-7 working days. If for any reason delivery time is longer than 7 working days, we will notify you.

![]()

If you would like to receive your delivery quicker, we have the option for pre-9am, pre-10am and pre-noon next day express delivery. We can also do the same with overseas deliveries.

![]()

Our parcels are sent via 1st Class Royal Mail Recorded Delivery. However, larger parcels will be sent via Fed Ex. All items will be shipped together unless due to unforeseen circumstances we are out of stock of a product. If this happens the said product will be placed on backorder. We aim for same day dispatch, most products will be dispatched within 2-3 days, the majority of stock products will be dispatched the same day if ordered by 1pm.

If you wish to collect your order, this can be arranged. Please kindly contact us first to ensure the item is available and collection is within our opening hours.

Please note: Once your item has been dispatched, we rely heavily on Royal Mail to deliver your items. If an item is thought to be lost in the post, we kindly ask you to check if your item is being held at your local Post Office. We are obliged to wait 15 working days from the dispatch date until we can resend your order. Royal Mail will not accept claims inside this 15 day period.

If for any reason Fed Ex is unable to deliver, they will try again the next working day, to request the consignment tracking number or for any further information regarding our deliveries please contact the office on +44 (0)1793 511000.

If goods have been damaged in transit, you must notify us within 48 hours of delivery to make a claim.

All returns to Bondline must be approved in advance.

If you want to return a purchased item for any reason, inform us on +44 (0)1793 511000 or email sales@bondline.co.uk to receive a returns reference or agreement. This reference must appear on the outside of the returned cartons and paperwork.

Return the product along with proof of purchase. Returned items must be defect-free and in a re-sellable condition and be returned within 30 days of purchase. If items are damaged a refund will not be provided. No product can be returned or credit issued for products after 30 days of purchase. A credit will be issued that can be used towards the purchase of any Bondline item. 20% will be deducted as a restocking charge.

You will be responsible for the safe return of unwanted items and the cost of returning it.

No restocking charge will apply to defective products or errors caused by Bondline.

If products are found to have fault, we will either dispatch a replacement item as soon as possible at no further cost. Alternatively we will repair the item and return and no extra cost.

The following items we are unable to accept return as per our terms and conditions of sale unless at Bondline’s fault:

For further information, please contact the sales team by calling 01793 511000 or sales@bondline.co.uk.

An ESD floor requires specialised care when it comes to cleaning. If you do not clean or maintain your antistatic floor, you could compromise the ESD properties of the floor. This could lead to expensive replacement costs of the damaged electronics and the floor itself. In order for your floor to perform its best long-term, cleaning it regularly with an ESD floor cleaner is essential.

Our ESD floor cleaner is an excellent choice for removing contaminations of ESD flooring and eliminating static. Before using a floor cleaner, we recommend to brush/sweep your ESD floor with an ESD dustpan and broom to clear it of all sand, grit, debris, or dirt.

ESD dustpans and brushes are usually made from static-safe materials such as ESD Polypropylene. The Black PP is formulated from anti-static raw material with no additional coating, making it permanently ESD safe. Most dustpan and brooms are made from high static materials – these should not be used in an electrostatic protected area. To protect your EPA from ESD damage, use our anti-static dustpan and broom.

For ESD floor mats, we recommend using our KILLSTAT Floor Cleaner for optimum results. This cleaner is suitable for cleaning vinyl and rubber flooring materials. To remove water-based floor finishes, we recommend using our KILLSTAT Restorer/Cleaner. This is a non-toxic, bio-degradable solution which has been developed for cleaning ESD floors without affecting the ESD properties. Effective for cleaning any sealed or hard floor finish, lower the resistivity and return the floor to safe and proper specifications.

View our full range of ESD floor treatment products by clicking here.

Since dirt can behave as an insulator, it is important to regularly clean ESD mats before testing / monitoring the resistivity. Accumulated flux and residue creates a barrier on an ESD table mat, which inhibits the mat’s ESD properties. This barrier, in effect, restricts the mat from being able to quickly dissipate the charge of the component or product being worked on. Cleaning will also ensure optimum electrical performance and, by regularly cleaning, you will maintain the original resistivity of the anti-static mat whilst extending its shelf-life.

For ESD mats, we recommend using our Staticide Mat and Table Top Cleaner for optimum results. This non-abrasive formula is safe to use on workstations, table tops and anti-static mats, including rubber and vinyl. It is the ideal cleaner for areas in which static-sensitive devices are assembled, tested, and handled, but can also be used in areas that require a mild but effective cleaner. Mat & Table Top Cleaner is a non-flammable cleaner that leaves no film or streaks. It effectively removes flux residues, oily finger-marks, grease, nicotine, dirt, grime and inorganic contaminants. It also removes dirt on chair mats and other antistatic mats without degrading the surface’s antistatic properties.

How To Use Staticide Mat and Table Top Cleaner:

1) Apply liberally to the areas to be cleaned.

2) Wait 2-3 minutes to allow emulsifiers to penetrate.

3) Then wipe it off.

NEVER use alcohol or silicone-based products to clean an ESD mat. Alcohol will dry out the mat, while silicone will create an insulating barrier. Ultimately, both alcohol and silicone will corrode the mat’s ESD properties.

View our full range of ESD cleaning products by clicking here.

To correctly maintain and clean your ESD smocks, you should wash the garment in warm or cool water, tumble dry with low heat (up to 60°C) or hang dry. We recommend to only use non-ionic softeners and detergents when laundering; do not use bleach to clean your clothes as this can erode the carbon threading.

The ESD lab coat’s and ESD lab jacket’s fabric is constructed using 65% polyester, 32% cotton and 3% conductive yarn.

The recommended washing guidance is a minimum of 60 industrial washes for an ESD lab coat and 50 industrial washes for an ESD lab jacket at a medium temperature. Size tolerance applies before washing. Washing can cause approximately 5% shrinkage for each garment, although this shouldn’t be noticeable or affect the static dissipative properties. Please note that the washing guidance can vary between each manufacturer. Reference washing ways GB12014-1989.

In addition, lab coats and jackets should not be altered in any way. The lab coats’ and jackets’ effectiveness is in fully covering the human body– particularly at the wrists and front of the body. Altering the lab coat or jacket in any way will reduce its effectiveness.

To discover why ESD Lab Coats and Jackets are essential for EPAs, click here.

To view our full range of ESD clothes, click here.

ESD flooring is an essential grounding solution that many businesses’ use to prevent electrostatic discharge in their static safe environments. It is widely used for industrial static control since many items in these areas are sensitive to static therefore prevention methods are required. By grounding the charge, anti-static flooring prevents the ESD from building up and discharging into the environment; where it could be destructive to goods or dangerous to people. To dissipate static, or draw static charges away from people or objects, the floor in any static-sensitive environment must be grounded. For electronics manufacturing applications that require the use of ESD footwear it’s fine to use charge-generating flooring materials like conductive vinyl.

If you intend to carry electrostatic sensitive devices around with you within the EPA, you should consider using ESD flooring in conjunction with the appropriate ESD footwear or ESD heel grounders to ground any static charge. Antistatic flooring should be installed in high-traffic/high-use networked environments to minimise static charge and to provide additional protection against static damage. ESD flooring should be installed anywhere the threat of uncontrolled static electricity buildup and discharge is a concern and could jeopardise the performance and operation of electronics systems or the handling, assembly and repair of electronics.

Click here to view our full range of ESD flooring.

Selecting a flooring for your business can be overwhelming with many to choose from; especially when you need to consider the materials, industry standards and requirements. Anti static flooring is often a beneficial choice for industries such as healthcare, electronics and military locations.

Controls static discharge

The main purpose of ESD flooring is to help reduce possible electrostatic discharge (ESD). ESD flooring is especially important within industries where static can cause interference or damage to employees and/or equipment. These can include: electronic and high tech areas, cleanrooms, operating theatres, classrooms and industrial areas.

Excellent for high-traffic/high-use networked environments

ESD flooring minimises static charge and provides additional protection against static damage.

Grounds people and products

ESD flooring ensures people and products are grounded in the static sensitive environment.

Durable

The majority of anti static floors are manufactured from hard-wearing and long-lasting materials such as rubber, tiles and vinyl.

Low maintenance

Both installation and care of ESD floors are generally extremely simple. Most ESD floors can often be placed over existing floors, interlock, and can be sealed easily with floor finish products. At Bondline, we offer the very best in pre-sales and after-sales service including a free floor audit, expert advice, full preparation and installation service, annual testing and calibration and a full cleaning and after-care service.

Easy to clean

An ESD floor requires specialised care when it comes to cleaning. If you do not clean or maintain your antistatic floor, you could compromise the ESD properties of the floor. This could lead to expensive replacement costs of the damaged electronics and the floor itself. In order for your floor to perform its best long-term you should use the appropriate floor treatments such as our ESD floor cleaner.

Click here to view our full range of ESD flooring materials.

If you are looking for a flooring solution for your workplace that controls static charge, you may be wondering what the difference is between ESD and anti static flooring and which one to purchase. Ultimately, each type of flooring prevents a person from building up a charge as they walk across the floor so they do not get a shock when they touch something that conducts electricity. However, the top layer of an anti-static floor has a coating that dissipates static across its surface so you never build up enough charge to get a shock, whereas ESD is a much more robust solution because it is actually earthed. ESD flooring gives a much higher level of protection than anti-static matting. This is because it is actually grounded.

The term anti-static refers to a very specific electrical resistance range of between 10⁹ and 10 to the 11 and only means that the floor itself will not generate static. It does not mean that the floor will eliminate static build up or dissipate static that may have already been built up in the body. This can only be achieved with a conductive (resistance range of between 10⁴ x 10⁶) or a dissipative (10⁷ to 10⁹) floor covering.

In general, you will need an ESD floor if you are manufacturing, repairing, servicing, handling or using equipment that is susceptible to damage from electro-static discharge, typical sectors would include the manufacture of components for the electronics industry, aviation, automotive, IT, medical, oil and gas, telecoms and IT for example. For electronics manufacturing applications that require the use of ESD footwear it’s fine to use charge-generating flooring materials like conductive vinyl.

In many cases it is possible depending on your current flooring. We recommend a site survey to establish whether this is possible or if your existing floor needs to be removed before the new ESD floor can be laid.

If you would like to discuss this further with our team, please contact us and we’ll get back to you as soon as possible.

Yes, in accordance with IEWC 61340-5-1 ESD footwear must be worn on both feet.

View our range of foot grounding products here.

Or, see our bestselling foot grounding product below.

When wearing heel straps/foot grounders in an ESD Protected Area, it is recommended that the conductive ribbon should make direct contact with the skin for maximum effectiveness. However, a conductive ribbon may be placed inside a wearer’s shoe underneath their sock to make electrical contact with the skin through perspiration. If the wearer chooses to place the ribbon underneath their sock, there are a few key factors you should consider. Socks can have varying material composition and thickness. Despite this, as long as the wearer’s feet are producing a sufficient sweat layer, it will make their socks conduct providing a conductive layer between each foot (skin) and grounding ribbon. Before handling electronic static-sensitive devices, ensure you allow enough time to develop a good layer of sweat in order to make the sock conductive enough to effectively bond the skin to the ribbon. You can check the continuity of the foot grounder via a footwear tester. If you would prefer to wear ESD shoes then please view our range here.

When applying a disposable heel strap, you should apply the strap within a static-controlled environment.

Step 1) Align the pressure-sensitive end of products with the front edge and centre of shoe heel.

Step 2) Peel the protective liner and mount the device. Press it firmly to the bottom of the heel.

Step 3) Wrap the contact ribbon of the heel grounder up the back of the shoe and lay it inside.

Step 4) Step into the shoe.

Step 5) Repeat steps one to four on the other shoe.

Wrist straps are not necessary if an operator is wearing two-foot grounders on a conductive grounded floor and doesn’t lift both heels/toes at the same time; like some people do when sitting down. If an operator is also wearing an ESD jacket but is not electrically connecting the jacket to either their body’s skin or ground, then the jacket is providing only partial protection.

Charges on the jacket may have nowhere to go or discharge to if the jacket is not grounded. A popular way to ground the jacket is with a coil cord either attached to a snap on the waist area of the jacket or via a wrist strap snapped to the inside cuff of an ESD jacket.

ESD wrist straps come in a variety of materials, but the general concept for each is the same; to provide a path for electrostatic ground.

For an ESD control wrist strap to work, it is either connected to earth bonding points fitted into workstations, typically via 10 mm press studs, or come with a removable coiled cord and crocodile clip for mobile applications.

The strap is fastened around your wrist using an adjustable band. The wristband should be worn snug to the skin with its coil cord connected to a common point ground which is connected to ground, preferably equipment ground. Typically, the alligator clip is attached to the computer or sensitive electronic device being worked on.

An anti static strap must be connected to a grounding source like a bonding plug in conjunction with a ground lead in order for them to be effective.

Once an ESD wrist strap has been secured to the wrist and connected to the earth bonding point or sensitive piece of equipment, you are safe to work without fear of ESD occurring. This allows you and your workforce to go about your daily tasks freely and drastically reduces the chances of static electricity building up.

The goal of using ESD wrist straps is to safely provide a way for static electricity to dissipate without causing electrostatic damage. The less ESD events that occur the better. An ESD protected work environment will enhance safety which helps to increase efficiency and production. While ESD wrist straps are highly effective pieces of equipment, it’s always best to support safety initiatives with the addition of ESD mats and other essential supplies. Short-term investments in high-quality ESD gear will pay off in the long-term.

Operators should use an anti static wristband to ensure any static discharge has a way to go from themselves to the ground safely. Without wearing a wristband whilst working on a static sensitive device/component you could effectively transfer static discharge onto the item and cause significant damage. This can be very costly to replace and time-consuming.

By wearing a wrist strap, you are not only taking an important step to prevent ESD from inflicting damage but you are also setting an example to your peers and managers.

There is no specific rule on a lifespan of a wrist strap. Any company policies should be followed on replacements but a good general rule of thumb is to look at the overall use, possible wear and cleanliness of your individual wrist strap.

Often companies determine a guideline on replacing them annually, semi-annually or quarterly.

This small change can often feel good for those that use a wrist strap daily and especially those who share a wrist strap at a common workbench or workstation.

It can be a small investment in employee satisfaction to have an upgrade to the tools and equipment on a regular basis. Replacing a wrist strap can be a small but strong signal from management that the company cares about proper ESD procedures.

Which wrist you decide to wear your anti static wrist strap on is often a matter of personal preference.

If you have the grounding point for the wrist strap cord on your left you may find wearing the wrist strap on your left makes the most sense. That way the cord isn’t dragging across your work.

However, you may find that it is better for you to move the grounding point to your right and then wear the wrist strap on your right hand.

Rubber matting should be used when you are working with chemicals and/or where high resistance to heat is required. It’s very durable and can be easily cleaned. Vinyl matting provides excellent static dissipation and it’s much more cost-effective opposed to rubber. It’s great for table-top work surfaces and can be easily cut into shape.

To view our ESD Matting range, please click here.

Yes, it is imperative to clean your bench mat regularly with an ESD bench mat cleaner. If your bench mat is dirty, your bench mat will become insulative which will generate static charges and transfer these charges to any static-sensitive device it comes into contact with. To check if your bench mat is dirty, we recommend using a Surface Resistivity Meter before using your mat to check its functionality. View our range of cleaning products by clicking here.

A constant monitor is highly recommended; however, it isn’t imperative to use one. When grounding yourself to Earth through the use of a wrist-strap, coil-cord and bonding plug, there’s a chance that you could become disconnected either from Earth, your wrist-strap, bench-mat or even the earth-to-ground system may be functioning incorrectly. This situation could happen at any stage whilst you are working. If you have no way of checking this, then you could be generating static charges and transferring them to static-sensitive devices which can cause damage. A constant monitor continuously monitors and identifies any problems with your wrist-strap, bench mat or the Earth whilst simultaneously checking the earth-to-ground system is working correctly. View our range of constant monitors here.

Surface resistivity meters are essential because they can check whether a surface is insulative, conductive or static-dissipative. They are used to measure surface resistivity and point-to-point resistance. It is vital that you regularly check your bench mat / floor mat with a surface resistivity meter to ensure it’s functioning correctly; if your matting is dirty, a surface resistivity meter can detect whether the surface has changed (usually from static-dissipative to insulative when the matting is dirty). Sometimes a dirty mat may not be clearly visible, so it’s best to check its surface before using it. View our surface resistivity meter here.

Bondline’s ESD training course will be carried out through the following:

Bondline can offer a comprehensive training facility, effective through personal involvement. This can be tailored to your requirements at your premises. Our knowledgeable team can offer guidance and training around ESD to help you learn more about what it is, the effects of it and more. Our training team have many years of experience of training people on ESD and have an abundance of knowledge about ESD themselves; so you can be sure you will be provided with the very best, expert trainers.

Bondline’s ESD training course is ideal for production personnel, engineers, support staff and managers. It is also suitable for those who would like to refresh their knowledge on ESD.

The training focuses on the causes of static generation, the effects of static discharge, and the materials and methods necessary for prevention and protection. The course content will reflect the facilities and current practice.

Understanding the phenomenon is enhanced through practical demonstrations and audience participation, allowing full engagement for the individual as a way of helping them to learn. Bondline provide various training course options so you can decide which one suits your needs best. Courses can be conducted in a small group or presented on a ‘one-to-one’ ‘train-the-trainer’ basis. For any questions regarding ESD that you may have, our experienced trainers will be happy to answer them during the training course. For any immediate questions about the training course itself, we’d love to have a chat with you to discuss these through.

Regarding costs, the pricing will depend on the amount of information/ training required. We can arrange to discuss training requirements and costs either via telephone or email. All training is designed to meet the requirements of IEC-61340-5.

Please contact us on 01793 511000 for further information and we can discuss the training course through with you.

**As Coronavirus restrictions ease, we will be offering our ESD training course to participants this year. Please make sure to contact us in advance to reserve your place and discuss your requirements.**

Each type of ESD wrist strap has been designed to be adjusted to fit each individual wearer. The two most common types of ESD wrist straps are metal ESD wrist straps and elastic adjustable ESD wrist straps. Each of these can be adjusted as follows:

Please read our blog post ‘Brexit and Bondline‘ to see how Brexit has impacted Bondline in terms of costs, delays, time and more.

Our quality focus is also at affordable and competitive prices, due to our extensive range of products, if you find a product cheaper elsewhere, please ask about our price matching. It could also be the product is not of the same quality. We can offer discounts on volume orders. Please get in touch to discuss.

At Bondline, we strive to offer affordable and competitive prices across our extensive product range for our customers. Throughout the year, we offer many types of discounts for our products. Additionally, all Bondline email subscribers will receive exclusive offers in our monthly newsletters before anyone else. To keep updated on our special discounts, sign up to our email newsletter today.

You can also find discounted products on our Special Offers and Clearance page where we have a wide range of products on offer.

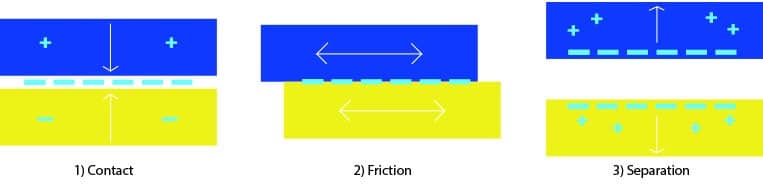

Electrostatic charges are generated when two surfaces come into contact with each-other then separate apart.

Yes, in accordance with IEWC 61340-5-1 ESD footwear must be worn on both feet.

View our range of foot grounding products here.

Or, see our bestselling foot grounding product below.

This is a tricky one and 2 points need to be considered.

1) If the water bottle is conductive and grounded then there is no issue.

2) If the water bottle is not conductive it may produce an electrostatic field. If this is the case then they need to be kept a safe distance from any electrostatic discharge sensitive device.

If the limits in IEC 61340 -5-1 are exceeded, the ESD control program shall include a tailoring. Tailoring is accomplished by evaluating the applicability of each requirement for the specific application. Upon completion of the evaluation, requirements may be added, modified or deleted. Tailoring decisions, including rationale and technical justification, shall be documented. (IEC 61340-5-1 5.1.3 Tailoring).

An example of this may be that the resistance of a floor exceeds the parameters of the IEC 61340 standard (ie greater that Rg < 1,0 × 109) If you can show that your controls are fit for purpose and keep the electro static discharge sensitive device safe by not exceeding the HBV of 100V.

1) If the electrostatic potential measured at the surface of the process required insulator exceeds 2,000 V, the item shall be kept a minimum of 30 cm from the ESDS; and

2) If the electrostatic potential measured at the surface of the process required insulator exceeds 125 V, the item shall be kept a minimum of 2,5 cm from the ESDS.

3) If the measured electrostatic field or surface potential exceeds the stated limits, ionization or other charge mitigating techniques shall be used.

This is usually in the datasheets of the individual components. It is often referred to as human body voltage (HBV).

Yes – an ESD floor is part of a system for personal grounding.

“For standing operations, personnel can be grounded via a wrist strap system or by a footwear-flooring system. When a footwear-flooring system is used, personnel shall wear ESD footwear on both feet and the two following conditions shall be met:

• The total resistance of the system (from the person, through the footwear and flooring to ground) shall be less than 1,0 × 109 Ω;

• The maximum body voltage generation shall be less than 100 V.” (IEC 61340-5-1 5.3.3)

View our range of ESD shoes here.

No, these signs are made from an insulative material which can generate a static charge. This could potentially harm nearby static-sensitive objects and cause significant damage to them. It is recommended to use ‘ESD signs’ outside of an EPA environment- this could be near your EPA’s entrance. View our ‘ESD signs’ range here.

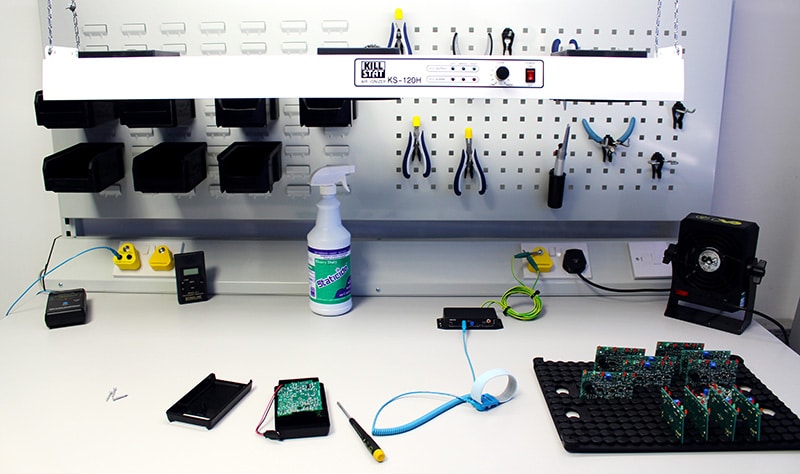

An Electrostatic Protected Area, also known as an EPA, is a designated area where static is controlled under strict regulations. A static safe handling area could be a bench, a room or any other designated area and should not have any ‘static field’ greater than 100v maximum. Within this designated area, all surfaces, objects, people and ESD Sensitive Devices (ESDs) are kept at the same electrical potential. All surfaces, products and people are bonded to Ground. Bonding means linking, usually through a resistance of between 1 and 10 meg ohms.

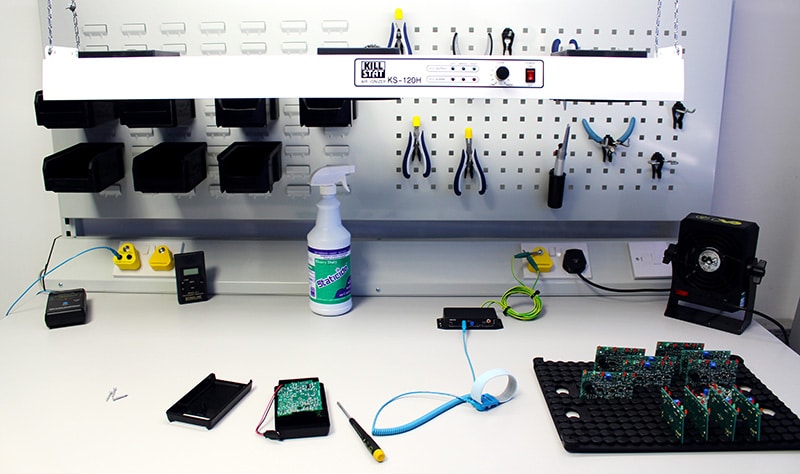

An EPA can be a small workstation or a large manufacturing area. These areas enable a safe environment for both operators and static-sensitive devices or components such as PCB boards that are prone to ESD damage. Equipment or products used within an EPA should qualify and comply to the IEC-61340-1-5 International Standard to ensure a safe, static-controlled environment. Everything that does not readily dissipate charge must be excluded from the EPA.

Essential EPA Equipment

When setting up your EPA consider using the following products:

Bench Top Ionizer, Continuous Monitor, Surface Resistivity Meter, ESD Tape, Worksurface Mats, Ground Cords, Overhead Ionizers, Shielding Bags, ESD Signs and Labels, Aisle Marking Tapes, ESD Floor Mats, Anti-Static Wrist Straps, ESD Foot Grounders, ESD Smocks, ESD Floor Maintenance and Anti-Static Binders and Sheet Protectors.

At Bondline Electronics, we are a leading manufacturer and supplier of Static Control products within the ESD Industry. Bondline offers an extensive range of ESD products to help you set-up your Electrostatic Protected Area (EPA). Discover our range of anti static products by clicking here.

Before setting up your ESD workstation, you will firstly need to refer to the most up to date IEC61340-5 standard which will give you all of the information you will need to set up an ESD workstation safely and within the current specification.

There are ESD protective workbenches, and selecting one would be the best practice. However, most companies use regular workbench. Materials used can vary, but it is best to use a workbench that is constructed of metal and wood, and not one containing large portions of high charging insulative plastic.

Most workstations will use pliable ESD matting to cover the bench and be the ESD work-surface on which to handle ESD sensitive (ESDS) items. The mat needs to be grounded and the best practice is to use metal grounding hardware snaps and ground cords connecting the work-surface mat to the common point ground. The entire bench-top should be covered by the ESD mat. Matting can be conductive or dissipative. Per ANSI/ESD S20.20 the required limit is less than 1 x 10E9 ohms and ANSI/ESD S4.1, the work-surface standard, recommends a low limit of 1 x 10E6 ohms. Per S4.1

A Working Surface Mat Grounding Cord and/or a Floor Mat Grounding Cord.

A basic ESD control rule is to ground all conductors including people at the ESD workstation. Grounding works great and will reliably remove ElectroStatic Charges to ground.

A Common Ground Point – An Earth Bonding Point (EBP) Plug or Bracket.

The first step in ensuring that everything in an EPA (ESD Protected Area) is at the same electrical potential is to ground all conductive components of the work area (work-surfaces, people, equipment, etc.) to the same electrical ground point. This point is called the common point ground. The next step in completing the ground circuit is to connect the common point ground to the equipment ground (third wire, green). Most locate the common point ground at the side edge of the workbench or towards the back of the bench-top.

Most workers, required for sitting workers, will be grounded via a wrist strap. The wrist strap needs to be selected and there needs to be an adequate number of ground points available. Even if typically the workstation is for only one worker, more than one ground point should be available to ground an additional worker, supervisor, or other ESD control element.

It is not required to have ESD flooring, but it could be selected to be low charging and/or a means to ground mobile equipment. Per S20.20, the required limit for Flooring is less than 1 x 10E9 ohms. For a standalone ESD workstation, a floor mat can be used with a ground cord connected to the workstation’s common point ground. We recommend conductive floor matting less than 1 x 10E6 ohms to be able to meet the Flooring/Footwear required limit of less than 3.5 x 10E7 ohms.

Instead of a wrist strap, a standing or mobile worker can be grounded using a Flooring/Footwear System. So ESD shoes or foot grounders can be selected. This means of personnel grounding requires both ESD flooring and ESD footwear. The ESD footwear is to be on both feet. Unless body voltage testing has been completed, the required limit per Compliance Verification ESD TR53 is of less than 3.5 x 10E7 ohms. The best practice is to use sole grounders or full coverage grounders and not heel grounders.

A bench-top ionizer or overhead ionizer can be selected to neutralize ElectroStatic charges at the workstation. This is the only ESD control method available to neutralize ElectroStatic charges on essential insulators or isolated conductors that may be at the workstation. The required limit per S20.20 is less than +/- 50 volts offset voltage (balance). In addition, the Discharge Times should be measured, both the time necessary to reduce +1,000 volts to +100 volts and the time necessary to reduce -1,000 volts to -100 volts.

ESD Bags, ESD Packaging, and ESD Storage.

Packaging and material handling containers at the ESD workstation should be low charging and have resistance (conductive or dissipative) so ElectroStatic charges can be removed to the ground. Shielding bags are also used additionally having the ESD control property of discharge shielding.

All items are made from small atoms. These atoms are made up of even smaller items called protons, neutrons and electrons. The protons are charged positive, the neutrons have no charge and the electrons are charged negative. Under normal conditions there are the same amount of protons and electrons giving atoms no charge.

However, these electrons can move. When separating or rubbing together of materials, electrons can move from atom to atom or from one material to another (triboelectric charging). This can mean that atoms can hold a positive or negative charge, (dependent on movement and direction of electrons). If the material in question is an insulator, this charge can be held and not move. This is called static electricity.

The rapid movement or decay of these charges can cause expensive problems, whether it is huge and dangerous charges such as lightening or simply an annoying (and sometimes painful) “electric shock” when touching a filing cabinet or when getting out of a car. (The charges are normally on you!).

These charges can be a huge problem for small sensitive electronic devices. Some devices can be damaged or destroyed by as little as 10 volts. Charges on your body, simply by walking or even sitting at your chair, can be in excess of 5000 volts, (human body model). This can be caused by items of clothing rubbing together or by shoes separating from insulating flooring such as carpets.

Imagine the damage this could cause. This is why it is important that insulators should be avoided and all possible static electricity generators (such as you) should (must) be grounded to eliminate any build up of charges.

The relative humidity (RH) directly affects the ability of a surface to store surface charges. The higher the RH, the less time an item will hold a charge. The method of surface charge reduction (due to increased RH) can be attributed to recombination and or conduction. As the RH increases, so does the natural conductivity of the air, but even at 100% RH the increase in the natural discharge rate cannot be substituted for proper ESD control practices.

E.S.D stands for ‘Electro Static Discharge’. An uncontrolled surge of ‘static’ between objects with different voltage potentials.

Conductive means low resistance (i.e. less than 1 meg-ohm (10^6) – the closer to 1 meg-ohm (10^6), the slower the discharge.)

Increased resistance, which protects better against an E.S.D (i.e. between 1 meg-ohm (10^6) and 1000 meg-ohm (10^9).

Does not allow the free flow of electrons, therefore, it will more than likely cause problems e.g. prevent a path to earth, hold a ‘static’ field, etc.

A conductive barrier against E.S.D (e.g. Metallised Shielding Bag, Conductive Box etc.)

If a component has ‘catastrophic’ damage it will show up in a test. However, ‘latent’ damage may not appear as a failure until later; i.e. tomorrow, next week, next month or even next year.

When wearing heel straps/foot grounders in an ESD Protected Area, it is recommended that the conductive ribbon should make direct contact with the skin for maximum effectiveness. However, a conductive ribbon may be placed inside a wearer’s shoe underneath their sock to make electrical contact with the skin through perspiration. If the wearer chooses to place the ribbon underneath their sock, there are a few key factors you should consider. Socks can have varying material composition and thickness. Despite this, as long as the wearer’s feet are producing a sufficient sweat layer, it will make their socks conduct providing a conductive layer between each foot (skin) and grounding ribbon. Before handling electronic static-sensitive devices, ensure you allow enough time to develop a good layer of sweat in order to make the sock conductive enough to effectively bond the skin to the ribbon. You can check the continuity of the foot grounder via a footwear tester. If you would prefer to wear ESD shoes then please view our range here.

Bench top ionisers are used to ensure a static free work area by neutralising static charge on insulated objects by producing a balanced source of positively and negatively charged ions. Its smaller size and lighter weight have made it more convenient to use which is great for workstations.

See our bench top ioniser range here.

Overhead ionisers ensure a static-free work area by neutralising static charge on insulated objects by producing a balanced source of positively and negatively charged ions. They are light-weight, quiet and are high-performing. The fans are independent of each other with individual controls and circuitry. These units have a built-in auto-balance feature with an out-of-balance alarm.

See our overhead ionisers here.

Air Ionization systems work by flooding the atmosphere with positive and negative ions. When the ionized air comes in contact with a charged surface, the surface attracts ions of the opposite polarity. As a result the static electricity that has built up on products and equipment is neutralised. Ions do remove small particles or smoke and pollens from the air, and subjective research suggest that people working in ionized area are happier.

Bondline’s ionizers eliminate the build-up of static charges on non-conductors, ensuring a static-free work area. Ionizers generate positive and negative ions which neutralise any static charges on insulating materials which cannot be grounded in the normal way. They are ideal for electronics industries which work with static-sensitive electrical components or devices.

We offer a range of ionizers to suit your requirements including:

Click here to view our full range of Ionizers.

The most significant environmental factor in ESD Control is the relative humidity (Rh). When humidity in the working environment decreases, the human body and other insulators can easily charge with static electricity due to friction. The air itself, being dry, becomes a part of the electrostatic build-up mechanism, every time an air flow (wind, air conditioning, blower) come over an insulated surface. Relative Humidity shall be maintained over 30%. Below that value it is recommended the use of ionization.

Conductors: Materials that easily transfer electrons (or charge) are called conductors and are said to have “free” electrons. Some examples of conductors are metals, carbon and the human body’s sweat layer. Grounding works effectively to remove electrostatic charges from conductors to ground. However, the item grounded must be conductive.

Insulators: Materials that do not easily transfer electrons are called insulators and are by definition non-conductors. Some well known insulators are common plastics and glass. An insulator will hold the charge and cannot be grounded and “conduct” the charge away.

Both conductors and insulators may become charged with static electricity and discharge. Grounding is a very effective ESD control tool; however, only conductors (conductive or dissipative) can be grounded.

Insulators, by definition, are non-conductors and therefore cannot be grounded. Insulators can be controlled by doing the following within an EPA:

When none of the above is possible, the insulator is termed “process essential” and therefore neutralisation using an ioniser should become a necessary part of the ESD control programme. An ioniser creates great numbers of positively and negatively charged ions. Fans help the ions flow over the work area. Ionisation can neutralise static charges on an insulator in a matter of seconds, thereby reducing their potential to cause ESD damage.

Note: Ionisers require periodic cleaning of emitter pins and the offset voltage must be kept in balance. Otherwise, instead of neutralising charges, if it is producing primarily positive or negative ions, the ioniser will place an electrostatic charge on items that are not grounded.

The primary function of an ioniser is to neutralise electrostatic charges on insulators and isolated (non-grounded) conductors to reduce the magnitude of electrostatic discharges in the ESD protected area.

A common example of insulators and isolated conductors is a populated circuit board where the board is a process essential insulator and often components on the board are isolated (non-grounded) conductors. Most companies handling electronics have such sub-assemblies in their products.

Also as electronic components become more ESD sensitive, many companies will want to add ionisers to improve their previously acceptable ESD control program.

If the ESD control program has not used ionization then that should be considered. If the ESD sensitive items becomes charged, ionization will help neutralize the charge. The primary function of ionizers with regard to ESD sensitive items include:

Bondline provide a full range of ESD Ionizers to help to eliminate the build-up of static charges on non-conductors, ensuring a static-free work area. Click here to browse the range.

On selected products if ordered before 1pm

Dedicated account manager to help your ordering process

Great value on premium quality products

Bondline Electronics uses cookies and tracking technologies to analyse our traffic, and for advertising/targeting purposes.

Cookie technology helps us to deliver content tailored to a visitor's interest, improve our site's performance and security, and makes a number of actions easier.

You can read more in our Privacy Policy and find out how to opt out at any time.