The Customer’s Requirements:

- A full site survey to discuss with the customer their needs.

- The customer is provided with various options of different flooring to suit their application.

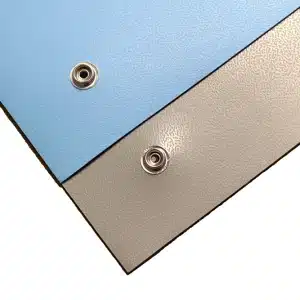

- A permanent ESD floor installed, fully fitted and tested to the current IEC61340-5 specification.

- A safe, ESD protected working environment.

At Bondline, we work very closely with all of our customers establishing their full ESD needs.

After working together with one of our largest customers – who were in the process of expanding – they decided that they required a new ESD floor to improve their quality and systems in order to provide a better service and ensure that they worked to the highest possible standards. Our customer chose Bondline to install their new ESD floor because they was confident that Bondline would be able to provide a solution for their brief, would suit their needs and go above their expectations.

After a full site survey of the current floor, discussing all of the available options and the preparation work that would be required, the customer came to a solution and opted for a permanent ESD floor.

As a result, Bondline’s ESD permanent floor was the most fitting solution for the area. The ESD permanent floor controlled the static discharge effectively in the sensitive areas. It also gave an aesthetically pleasing appearance, enhancing the commercial interior. With the floor fully complying with all ESD standards and cleanroom standards, the manufacturer could be assured that all standards we met and provided a safe-ESD protected working environment. Furthermore, the range of colour options enabled the manufacturer to have sectioned areas such as walkways. Click here to view our ESD permanent flooring solution.

The Following Tasks Were Completed:

- Disposal of the old floor.

- Screeding the current floor with a levelling compound to ensure that the floor was correctly levelled. This ensured that it would be ready for the laying of the new ESD floor tiles.

- Full installation of new ESD floor.

- Full testing and certification to confirm that the floor met the current IEC61340-5 standard.

Disclaimer: ESD Floor Installation was conducted before the Coronavirus pandemic – all images shown were taken before the pandemic.

Benefits of using Bondline for your ESD Floor Installation:

- Over 30 years’ experience of installing ESD flooring.

- Advice on floor preparation and most appropriate material to use.

- Variety of materials to choose.

- Complete supply, deliver and install package.

- Installation by our recommended fitters with experience of floor installations.

- Test Certification.

- Annual testing/certification if required.

When establishing an electrostatic protected area (EPA), making the correct choice of ESD flooring is essential to ensure that sensitive electronic components and assemblies are adequately protected from the harmful effects of electrostatic discharge (ESD).

To view our full range of ESD floor materials, click here.

For general enquiries or to discuss about ESD floor installations, please contact us.

The Bondline Team.

![Anti-Skid-Polypropylene-ESD-Shoe-Cover-Blue-LG_main-02[2] - Bondline Anti Skid Polypropylene ESD Shoe Cover Blue Bondline](https://www.bondline.co.uk/wp-content/uploads/2019/08/Anti-Skid-Polypropylene-ESD-Shoe-Cover-Blue-LG_main-022-300x300.jpg)