A Trusted UK Supplier Of ESD Control Products Since 1986

A Trusted UK Supplier Of ESD Control Products Since 1986

How Well Does Relative Humidity Of The Surrounding Atmosphere Control The ESD?

The relative humidity (RH) directly affects the ability of a surface to store surface charges. The higher the RH, the less time an item will hold a charge. The method of surface charge reduction (due to increased RH) can be attributed to recombination and or conduction. As the RH increases, so does the natural conductivity of the air, but even at 100% RH the increase in the natural discharge rate cannot be substituted for proper ESD control practices.

What Is Static Electricity?

All items are made from small atoms. These atoms are made up of even smaller items called protons, neutrons and electrons. The protons are charged positive, the neutrons have no charge and the electrons are charged negative. Under normal conditions there are the same amount of protons and electrons giving atoms no charge.

However, these electrons can move. When separating or rubbing together of materials, electrons can move from atom to atom or from one material to another (triboelectric charging). This can mean that atoms can hold a positive or negative charge, (dependent on movement and direction of electrons). If the material in question is an insulator, this charge can be held and not move. This is called static electricity.

The rapid movement or decay of these charges can cause expensive problems, whether it is huge and dangerous charges such as lightening or simply an annoying (and sometimes painful) “electric shock” when touching a filing cabinet or when getting out of a car. (The charges are normally on you!).

These charges can be a huge problem for small sensitive electronic devices. Some devices can be damaged or destroyed by as little as 10 volts. Charges on your body, simply by walking or even sitting at your chair, can be in excess of 5000 volts, (human body model). This can be caused by items of clothing rubbing together or by shoes separating from insulating flooring such as carpets.

Imagine the damage this could cause. This is why it is important that insulators should be avoided and all possible static electricity generators (such as you) should (must) be grounded to eliminate any build up of charges.

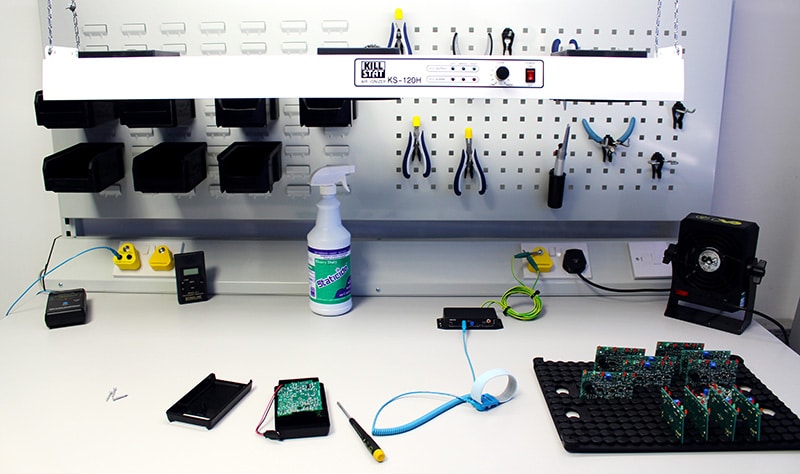

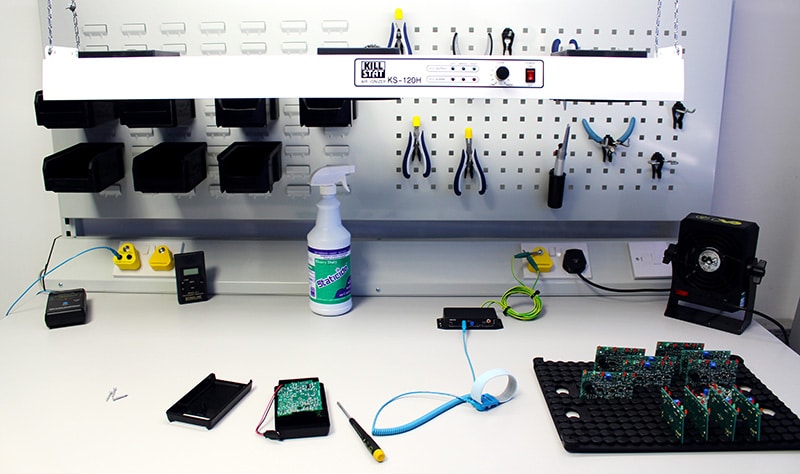

How Should I Set Up An ESD Workstation?

Before setting up your ESD workstation, you will firstly need to refer to the most up to date IEC61340-5 standard which will give you all of the information you will need to set up an ESD workstation safely and within the current specification.

There are ESD protective workbenches, and selecting one would be the best practice. However, most companies use regular workbench. Materials used can vary, but it is best to use a workbench that is constructed of metal and wood, and not one containing large portions of high charging insulative plastic.

Most workstations will use pliable ESD matting to cover the bench and be the ESD work-surface on which to handle ESD sensitive (ESDS) items. The mat needs to be grounded and the best practice is to use metal grounding hardware snaps and ground cords connecting the work-surface mat to the common point ground. The entire bench-top should be covered by the ESD mat. Matting can be conductive or dissipative. Per ANSI/ESD S20.20 the required limit is less than 1 x 10E9 ohms and ANSI/ESD S4.1, the work-surface standard, recommends a low limit of 1 x 10E6 ohms. Per S4.1

A Working Surface Mat Grounding Cord and/or a Floor Mat Grounding Cord.

A basic ESD control rule is to ground all conductors including people at the ESD workstation. Grounding works great and will reliably remove ElectroStatic Charges to ground.

A Common Ground Point – An Earth Bonding Point (EBP) Plug or Bracket.

The first step in ensuring that everything in an EPA (ESD Protected Area) is at the same electrical potential is to ground all conductive components of the work area (work-surfaces, people, equipment, etc.) to the same electrical ground point. This point is called the common point ground. The next step in completing the ground circuit is to connect the common point ground to the equipment ground (third wire, green). Most locate the common point ground at the side edge of the workbench or towards the back of the bench-top.

Most workers, required for sitting workers, will be grounded via a wrist strap. The wrist strap needs to be selected and there needs to be an adequate number of ground points available. Even if typically the workstation is for only one worker, more than one ground point should be available to ground an additional worker, supervisor, or other ESD control element.

It is not required to have ESD flooring, but it could be selected to be low charging and/or a means to ground mobile equipment. Per S20.20, the required limit for Flooring is less than 1 x 10E9 ohms. For a standalone ESD workstation, a floor mat can be used with a ground cord connected to the workstation’s common point ground. We recommend conductive floor matting less than 1 x 10E6 ohms to be able to meet the Flooring/Footwear required limit of less than 3.5 x 10E7 ohms.

Instead of a wrist strap, a standing or mobile worker can be grounded using a Flooring/Footwear System. So ESD shoes or foot grounders can be selected. This means of personnel grounding requires both ESD flooring and ESD footwear. The ESD footwear is to be on both feet. Unless body voltage testing has been completed, the required limit per Compliance Verification ESD TR53 is of less than 3.5 x 10E7 ohms. The best practice is to use sole grounders or full coverage grounders and not heel grounders.

A bench-top ionizer or overhead ionizer can be selected to neutralize ElectroStatic charges at the workstation. This is the only ESD control method available to neutralize ElectroStatic charges on essential insulators or isolated conductors that may be at the workstation. The required limit per S20.20 is less than +/- 50 volts offset voltage (balance). In addition, the Discharge Times should be measured, both the time necessary to reduce +1,000 volts to +100 volts and the time necessary to reduce -1,000 volts to -100 volts.

ESD Bags, ESD Packaging, and ESD Storage.

Packaging and material handling containers at the ESD workstation should be low charging and have resistance (conductive or dissipative) so ElectroStatic charges can be removed to the ground. Shielding bags are also used additionally having the ESD control property of discharge shielding.

What Is An Electrostatic Protected Area (EPA)?

An Electrostatic Protected Area, also known as an EPA, is a designated area where static is controlled under strict regulations. A static safe handling area could be a bench, a room or any other designated area and should not have any ‘static field’ greater than 100v maximum. Within this designated area, all surfaces, objects, people and ESD Sensitive Devices (ESDs) are kept at the same electrical potential. All surfaces, products and people are bonded to Ground. Bonding means linking, usually through a resistance of between 1 and 10 meg ohms.

An EPA can be a small workstation or a large manufacturing area. These areas enable a safe environment for both operators and static-sensitive devices or components such as PCB boards that are prone to ESD damage. Equipment or products used within an EPA should qualify and comply to the IEC-61340-1-5 International Standard to ensure a safe, static-controlled environment. Everything that does not readily dissipate charge must be excluded from the EPA.

Essential EPA Equipment

When setting up your EPA consider using the following products:

Bench Top Ionizer, Continuous Monitor, Surface Resistivity Meter, ESD Tape, Worksurface Mats, Ground Cords, Overhead Ionizers, Shielding Bags, ESD Signs and Labels, Aisle Marking Tapes, ESD Floor Mats, Anti-Static Wrist Straps, ESD Foot Grounders, ESD Smocks, ESD Floor Maintenance and Anti-Static Binders and Sheet Protectors.

At Bondline Electronics, we are a leading manufacturer and supplier of Static Control products within the ESD Industry. Bondline offers an extensive range of ESD products to help you set-up your Electrostatic Protected Area (EPA). Discover our range of anti static products by clicking here.

Can I use ESD signs within my EPA?

No, these signs are made from an insulative material which can generate a static charge. This could potentially harm nearby static-sensitive objects and cause significant damage to them. It is recommended to use ‘ESD signs’ outside of an EPA environment- this could be near your EPA’s entrance. View our ‘ESD signs’ range here.

Do we need to wear ESD footwear on an ESD floor?

Yes – an ESD floor is part of a system for personal grounding.

“For standing operations, personnel can be grounded via a wrist strap system or by a footwear-flooring system. When a footwear-flooring system is used, personnel shall wear ESD footwear on both feet and the two following conditions shall be met:

• The total resistance of the system (from the person, through the footwear and flooring to ground) shall be less than 1,0 × 109 Ω;

• The maximum body voltage generation shall be less than 100 V.” (IEC 61340-5-1 5.3.3)

View our range of ESD shoes here.

How can I find out how sensitive a component is?

This is usually in the datasheets of the individual components. It is often referred to as human body voltage (HBV).

What can we do if some of the tools within our production are insulators and create an electrostatic field that could be harmful to our components?

1) If the electrostatic potential measured at the surface of the process required insulator exceeds 2,000 V, the item shall be kept a minimum of 30 cm from the ESDS; and

2) If the electrostatic potential measured at the surface of the process required insulator exceeds 125 V, the item shall be kept a minimum of 2,5 cm from the ESDS.

3) If the measured electrostatic field or surface potential exceeds the stated limits, ionization or other charge mitigating techniques shall be used.

What do we do if we cannot comply with IEC 61340 5-1 (ie floor resistance too high, manufacture a product with insulators)

If the limits in IEC 61340 -5-1 are exceeded, the ESD control program shall include a tailoring. Tailoring is accomplished by evaluating the applicability of each requirement for the specific application. Upon completion of the evaluation, requirements may be added, modified or deleted. Tailoring decisions, including rationale and technical justification, shall be documented. (IEC 61340-5-1 5.1.3 Tailoring).

An example of this may be that the resistance of a floor exceeds the parameters of the IEC 61340 standard (ie greater that Rg < 1,0 × 109) If you can show that your controls are fit for purpose and keep the electro static discharge sensitive device safe by not exceeding the HBV of 100V.

Can we bring water bottles in an EPA?

This is a tricky one and 2 points need to be considered.

1) If the water bottle is conductive and grounded then there is no issue.

2) If the water bottle is not conductive it may produce an electrostatic field. If this is the case then they need to be kept a safe distance from any electrostatic discharge sensitive device.

On selected products if ordered before 1pm

Dedicated account manager to help your ordering process

Great value on premium quality products