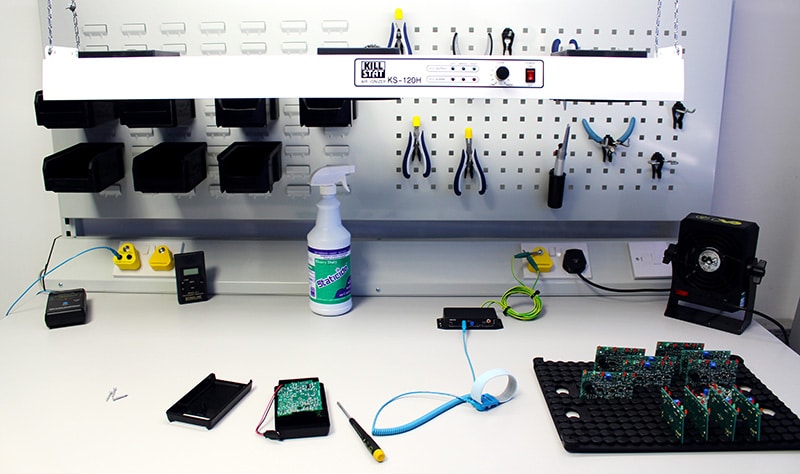

In an Electrostatic Protected Area, it is important to keep your ESD workstation clean and free of contaminants on a regular basis. Regular cleaning and care will help to extend the lifespan of your ESD workstation as well as maintain its ESD protective properties. In this article, we’ll provide our top tips for cleaning an ESD workstation to help maintain a safe and clean work environment.

One of the most common causes of change in surface resistance is dirt. Dirt contributes to many electronic component and device failures. A build-up of dirt on static sensitive electronic components or devices can cause the products to malfunction or poorly perform. This can cause significant downtime and loss of productivity. To eliminate dirt and prevent static damage, cleaning all surfaces in an EPA is paramount to a static safe area.

To maintain a safe and clean EPA, it is important to clean all equipment at the workstation that are most often used or touched and can get dirty quickly. You should consider cleaning:

When cleaning an ESD workstation, it is crucial to pay attention to the floor as well as the wheels on trolleys, chairs and drawer units.

In areas where there is heavy foot traffic, flooring can become dirty very quickly. This can cause a build-up of dirt to form on the wheels of trolleys, drawer units and chairs, increasing the risk of ESD.

Equipment with electrostatic discharge protection properties must be carefully cleaned with appropriate cleaning supplies and formulas. Cleaning the equipment with Dettol, IPA wipes, normal cleaners or general anti-bacterial products could risk damaging the ESD protective features. It is recommended to use a mild, multi-purpose neutral cleaner that does not contain any harsh solvents or chemicals. It is best to avoid applying wax and coatings as these will create an insulated layer on the surfaces.

The type of cleaning tool used to clean the surfaces is also important to factor in. Care should be taken to avoid contact with abrasive cleaning tools (i.e. sandpaper, scrubbers, sponges), brushes and sharp objects as these can cause damage to the surfaces and therefore compromise the ESD protective properties. A soft, microfibre cloth should only be used to wipe down the surfaces.

Make sure to advise the cleaners on the correct supplies and formulas to use for cleaning the surfaces in the EPA. Ensure that they understand the importance of the ESD protective surfaces.

Most types of ESD protective clothing can be machine-washed or dry cleaned. Always check the washing instructions before cleaning the clothes.

1. Get high-quality and appropriate cleaning supplies and keep them easily accessible.

2. Leave sufficient time for the task.

3. Ensure proper lighting.

4. Follow the dosage instructions on the packaging of detergents and disinfectants. Too much of the substance will not improve the cleaning result and may possibly damage the surface and create irremovable stains on the surface.

5. Use only a soft cloth to wipe the surfaces, e.g. microfibre wipes. Abrasive cleaning materials must not be used.

6. Clean paint work periodically with warm soapy water.

7. Clean worktop surfaces periodically with warm soapy water or proprietary surface cleaners. Do not use solvents of any type.

8. Where cupboards and drawers are fitted, periodically oil hinges and locks sparingly with a light oil (3-in-1 or similar).

9. Cleaning directions: a) From top to bottom, b) From clean towards dirtier areas.

10. Always wipe the surface with a dry or only slightly moist cloth and leave to dry.

11. Educate and train new and existing employees on the ESD control measures for cleaning ESD workstations.

12. Audit the EPA to check that all cleaning practices are within compliance to the IEC 61340-5-1 Standard.

It is important to use the correct type of cleaning products to clean your ESD workstation. The type of surface will determine which type of cleaning product you need to use. Below is a list of the types of cleaning products to use for each type of ESD control equipment.

To maintain the original surface resistivity of anti-static mats and workbenches, they must be regularly cleaned with an ESD cleaning solution that has been specially formulated for cleaning anti-static surfaces.

You should look for a cleaner that contains no alkali, ammonia or chemical on RoHS and REACH SvHC. The product should leave no film or streaks and meet the latest ESD industry standards. An example of a good ESD mat and bench cleaner is our Staticide Mat and Table Cleaner.

ESD wipes can also be used for the safe cleaning of ESD mats and workbenches. Our Staticide® wipes have the same long-lasting protection against static as our Staticide® topical liquids, but offer a one-step cleaning and static control solution.

ESD carpets, upholstery and fabrics require a much more durable cleaning solution to eliminate static and dirt. It is recommended to use a Heavy Duty Staticide Anti Static Spray to eliminate static charge and prevent tribogeneration on carpets, upholstery, and fabrics (i.e. the fabric on ESD chairs at a workstation).

Keeping your ESD floor clean of dust, dirt and contaminants is important in maintaining the static protective properties and efficacy of the ESD floor system. A build-up of dirt on the top layer of the flooring can prevent the flooring from working properly. An ESD Dustpan and Broom is great for giving the floor an initial clean, removing any loose dirt or debris from the surface layer of the flooring.

A dustpan and broom will only clean the surface of the flooring. To completely eliminate static and dirt, the ESD floor must be washed with an ESD safe floor cleaner. Cleaning your ESD floor with a specially formulated floor cleaner will thoroughly clean the floor, providing long-lasting static control.

Non-porous surfaces such as carriers and tote boxes can be safely cleaned with a specially formulated ESD cleaner for non-porous surfaces. Non-porous cleaners such as our Anti-Static General Purpose Staticide Spray are ideal for eliminating static and dirt on plastic parts, equipment, and rubber.

To ensure that all insulative contaminants such as grime and dirt have been completely removed from the workstation, it is recommended to test the surface of your workbench, anti-static matting and ESD flooring or floor mats.

To test the surfaces, we recommend using a Surface Resistivity Meter. A Surface Resistivity Meter can measure the point-to-point resistance and the resistance-to-ground of the surface. The surface resistance must meet 10^(8) ohms to ensure compliance to the ESD working standards. You should aim to test your surfaces regularly to ensure they are providing the most adequate ESD protection.

While measuring, make sure to write down the ESD values in the ESD Control Plan. By following your ESD Control Plan, cleaning and measuring, the protection rate of your Electrostatic Protected Area will stay at the same level for many years to come.

We hope our tips for cleaning an ESD workstation have given you a better understanding on how to maintain a clean and safe EPA. The next step is to select and purchase the cleaning supplies you need for your ESD workstation. Bondline stock a wide range of static control cleaning supplies for the safe cleaning of ESD workstations.

For more advice on cleaning an ESD workstation, please get in touch with our Sales Team on +44 (0)1793 511000 or sales@bondline.co.uk.

Fields marked with an * are required

On selected products if ordered before 1pm

Dedicated account manager to help your ordering process

Great value on premium quality products

Bondline Electronics Ltd are a leading manufacturer and supplier of static control products within the ESD industry. Products such as Flexible and Rigid Packaging, Bench Matting, Wrist Straps, Heel Grounders and Shoes, ESD Protective Clothing and Gloves, Test and Measurement Equipment along with many storage and handling solutions.

Bondline products are all qualified and compliant according to IEC-61340-5-1 International Standard.

Registered Company Number: 02933918

Office Hours: Mon – Thurs: 9am – 5pm Fri: 9am – 2pm

Bondline Electronics Ltd are a leading manufacturer and supplier of static control products within the ESD industry. Products such as Flexible and Rigid Packaging, Bench Matting, Wrist Straps, Heel Grounders and Shoes, ESD Protective Clothing and Gloves, Test and Measurement Equipment along with many storage and handling solutions.

You cannot copy content of this page

Some of these cookies are essential, while others help us to improve your experience by providing insights into how the site is being used.

For more information and to read more about our privacy policy, please visit our Privacy Policy

Necessary cookies enable core functionality. The website cannot function properly without these cookies, and can only be disabled by changing your browser preferences.