Anti static wipes: An easy and effective way of dealing with ESD. Anti static wipes are an innovative, safe, and wipe-clean method of eliminating static charge on surfaces. Keeping your electronics and equipment clean and static-free is paramount to effective ESD control. In this article, we will be delving into anti static wipes; discussing what they are and how they work.

Article contents:

Anti static wipes are a must-have in electronics manufacturing and electronic assembly cleanrooms. They are an effective anti-static applicator for keeping electronic devices, work equipment, and industrial machinery parts clean from static charge, dust build-up and dust attraction. The wipes are safe to use, practical and are an easy alternation to standard chemical cleaning products.

ESD wipes can be used on all static sensitive surfaces. They are particularly effective for cleaning ESD mats, test equipment, euro boxes, bins, tools, lights, work benches, and soldering gear. There are various types of anti static wipes in the market; one of the most common types being pre-saturated ESD wipes. Pre-saturated ESD wipes contain a cleaning agent that quickly evaporates after use. These wipes are most effective in cleaning connectors and cables. They are also great for quickly and thoroughly removing flux residues, fingerprints, grime, oils, and debris with ease.

Many electronic companies opt for anti static wipes over alternate topical liquids because they offer quick and convenient cleaning. In addition to this, many of these topical liquids contain toxic ingredients which can be hazardous to the environment. You will find that most anti static wipes such as the Staticide® brand are non-toxic and biodegradable which makes them the ideal choice for static cleaning and helping to protect the environment.

A cleanroom setting, in an electronic assembly environment, is particularly vulnerable to contamination. Electronic products manufactured within a cleanroom environment are highly sensitive – even the smallest particles can lead to catastrophic damage. Damage caused by contaminants can be expensive, particularly in recall costs. While contaminants are one issue, static electricity poses to be an added challenge to the cleanroom environment. Therefore, further specialised equipment and routines must be implemented, such as anti static wipes.

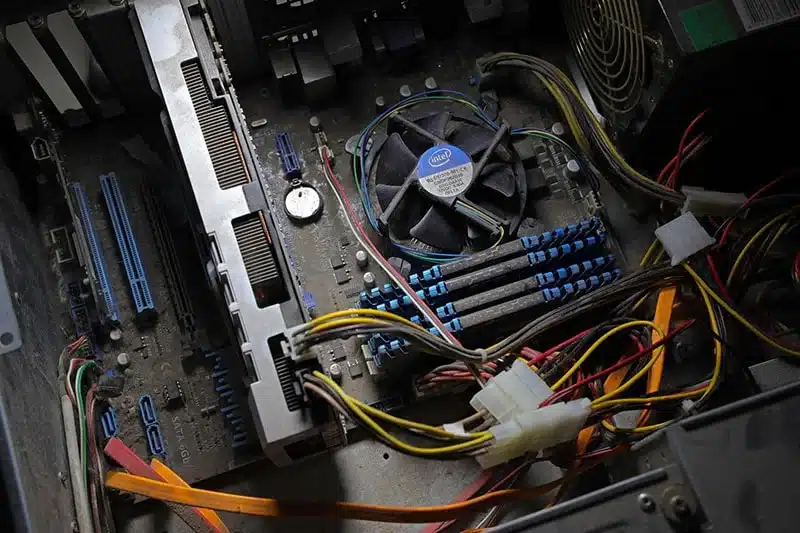

Dust accumulation can be a nuisance when it comes to electronics, particularly in environments such as data centres, server rooms, electronics manufacturing, hospitals, and offices where electronics performance is relied upon to work efficiently and as intended to. As dust builds-up, settles and thickens overtime, it can reduce the reliability, functionality, and lifespan of the electronic device; eventually blocking important components like fans. Dust that is left to amass can result in a myriad of issues, including the following:

Fortunately, there are methods to reduce dust accumulation and keep your electronics and equipment at bay from static charge. Anti-static wipes are an excellent way to combat this.

There are many different brands that supply anti static wipes; Staticide® is one of these. Below, we will discuss Staticide® wipes in more detail and the benefits their wipes have to offer.

The ultimate towelette for cleaning and static control. Staticide® wipes are a popular choice when it comes to selecting anti static wipes for your Electrostatic Protected Area. Unlike some anti-stats, Staticide® topicals and wipes are not dependent on humidity to be effective. These types of wipes will meet MIL-B-81705 for static decay even in dry conditions and low humidity.

Staticide® wipes have the same long-lasting protection against static as Staticide® topical liquids but offer a one-step cleaning and static control solution. They are safe to use around electronics, and since Staticide® will prevent dust build-up and dust attraction, computer and laptop screens will stay clean for longer just by wiping the plastic housing. Though, care should be taken not to wipe directly onto the electronics’ screen.

Apart from using on materials that are adversely affected by water or alcohol, they are great for cleaning hard surfaces such as plastic, non-painted metal or glass. While Staticide® wipes can be used on industrial machinery and parts, and they are also great to use in tight spaces.

Now that we know what an anti-static wipe is and its uses, we will move on to how it works.

In an ESD environment, it is critical to prevent the build-up of static charge in order to protect static sensitive components from static damage. Using an anti static wipe enables you to not only clean surfaces and equipment, but also helps to lower the build-up of static electricity (E.S.D).

Anti static wipes are very easy to use. Compared to anti static topical liquids, anti static wipes only require one step before use; keeping cleaning routines hassle-free and quick. For an anti static wipe to work, the wipe simply needs to be removed from its packaging and then unfolded apart, ready to polish a surface. Cleaning a surface with an anti static wipe will remove any contaminants such as fingerprints, debris or flux residues as well as eradicate any static charge present.

While ESD wipes can be used to safely clean hard surfaces like glass, vinyl, and plastic, they should not be used directly on computer screens. Often at times, streaking on surfaces can occur. If there happens to be streak marks on the electronic device or equipment, the towelette should be allowed to partially dry before re-wiping the surface.

The wipes are most effective when used on a regular basis; we recommend using them at least once a week. Since they are safe to be used around electronics, they are ideal for use in an Electrostatic Protected Area (E.P.A).

While anti static wipes can help to eliminate static charges on surfaces, they are only a temporary solution to static control. Incorporating a full ESD Control System to your workplace will not only provide a long-term static control solution, but will also improve electronics’ safety against ESD. If you’d like to learn more about ESD and the materials and methods necessary for prevention, consider taking Bondline’s ESD training course by calling us on +44 (0)1793 511000. Designed to meet the requirements of IEC-61340-1-5, the course is ideal for production personnel, engineers, support staff, managers and those wanting to refresh their knowledge of ESD.

We hope this article has helped you understand more about anti static wipes and how they work to eliminate ESD. In the meantime, if you have any further questions about ESD wipes, please don’t hesitate to get in touch with us on the form below. In our next article, we will be looking at ESD safety essentials for an Electrostatic Protected Area.

Fields marked with an * are required

On selected products if ordered before 1pm

Dedicated account manager to help your ordering process

Great value on premium quality products

Bondline Electronics Ltd are a leading manufacturer and supplier of static control products within the ESD industry. Products such as Flexible and Rigid Packaging, Bench Matting, Wrist Straps, Heel Grounders and Shoes, ESD Protective Clothing and Gloves, Test and Measurement Equipment along with many storage and handling solutions.

Bondline products are all qualified and compliant according to IEC-61340-5-1 International Standard.

Registered Company Number: 02933918

Office Hours: Mon – Thurs: 9am – 5pm Fri: 9am – 2pm

Bondline Electronics Ltd are a leading manufacturer and supplier of static control products within the ESD industry. Products such as Flexible and Rigid Packaging, Bench Matting, Wrist Straps, Heel Grounders and Shoes, ESD Protective Clothing and Gloves, Test and Measurement Equipment along with many storage and handling solutions.

Some of these cookies are essential, while others help us to improve your experience by providing insights into how the site is being used.

For more information and to read more about our privacy policy, please visit our Privacy Policy

Necessary cookies enable core functionality. The website cannot function properly without these cookies, and can only be disabled by changing your browser preferences.