Air ionisation is increasingly being used in many industries and critical environments to neutralise or control static charges. In an Electrostatic Protected Area, there are often times where items such as masking tapes or product plastic housing cannot be grounded to Earth. While some of these items can be simply removed from the EPA or swapped for an ESD protective version, others may be necessary to use to complete operations. A core principle of ESD control is to neutralise “process-essential” insulators with the use of ESD ionisers.

In this article, we will cover the basics of an ioniser, the types of ionisers there are for ESD control and how they function. We will also provide you with our top-tips on choosing the right type of ioniser for your application.

In industries where printed circuit boards, SMDs or other electronics assembly equipment are manufactured, it is critical to remove electrostatic discharge (ESD) and particle contamination to prevent irreversible damage to static sensitive components. One method to protect your production line process is by utilising ionisers.

Ionisers are specialised devices that help to remove static charge on objects and surfaces by passing an electrical charge to molecules in the air. The primary function of an ioniser is to neutralise electrostatic charges on “process-essential” insulators and isolated (non-grounded) conductors.

An insulator is classed as a non-conductor and therefore cannot be grounded. Insulators can usually be controlled by either replacing the insulative items with an ESD protective version or by removing them from the EPA. When either of these options are not possible, the insulator is known as “process-essential”.

ESD workstations in an Electrostatic Protected Area often have “process-essential” insulators (i.e. product plastic housing or PC board substrate) or isolated conductors (i.e. conductive traces or printed circuit board components not in contact with ESD worksurface) that cannot be removed or replaced. “Process-essential” insulators are necessary to build or assemble the finished product. When grounding of these is not possible, choosing a method to neutralise electrostatic charge is necessary. This can be achieved with ionisation.

1. Neutralise electrostatic charges on process-essential insulators

2. Minimise electrostatic charges on isolated conductors

3. Eliminate particulate contamination

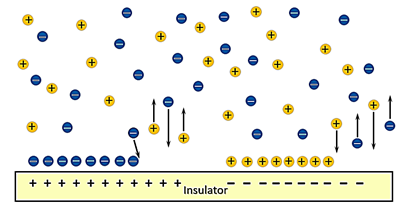

An ioniser works by creating a vast number of positively and negatively charged ions. These ions are then sent out into the atmosphere. Fans help these charged ions flow over the work area. When the ions make contact with a charged surface, the surface attracts ions of the opposite polarity. As a result, the built-up electrostatic charges on the equipment, products, or surfaces in your immediate workspace is neutralised, thereby reducing their potential to cause ESD damage to static sensitive components.

Airflow is often needed to help some ionisers operator properly. When using ionisers that require airflow, it is important to understand that these ionisers will be dependant on available airflow or include fans in their design. If the ionisers include fans in their design, they must be weighed for their compatibility with the work area.

Ionisers can be used in various types of environments where static charge and particle contamination must be controlled. Several types of applications where ionisers are commonly used include the following:

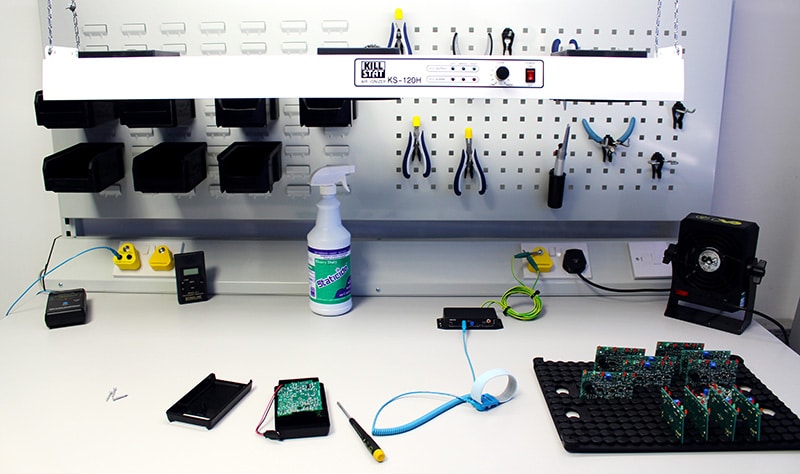

Bench top ionisers are commonly used due to their compact build and ability to be easily moved from one workbench to another. This can help save costs for small EPAs with a few operators and shared workload if the ioniser is moved between each bench. They are simple to use, and routine maintenance can be performed with ease.

Their smaller size and lighter weight make the bench top ioniser a more convenient choice for workstation ionisation. While they generally require only little production space, some types of bench top ionisers can be suspended above the bench using a flexible mounting arm, wall-mounted or placed on a shelf.

With a bench top ioniser, it is imperative that items on the workbench must not obstruct the flow of ionised air.

When work station space is limited, overhead ionisers are a good option to use. Overhead ionisers were established to help solve the problem of items on a bench blocking the flow of ionised air. With an overhead ioniser, downward airflow is more consistent over the entire bench. Compared to other types of ionisers, overhead ionisers are quiet and high-performing.

There are various types of precision air ionisers for ESD control. Two of the most common types include air ioniser guns and ionising air snakes. Precision air ionisers use compressed air to neutralise static charges in localised areas. They are a good option for removing contamination such as dust or debris while simultaneously eliminating static attraction particles on a static sensitive device. ESD guns and other types of forced air ionisers are typically used in the cleanroom industry where particle contamination is strictly controlled. Whereas an air ioniser gun requires hand-held operation, an ionising air snake is a great choice to use when hands-free operation in a confined space is required.

While there is no best type of ioniser technology for all applications, there are several key factors to keep in mind when determining the most appropriate type of ioniser to use.

Our team will provide you with their expert advice on choosing the best type of ioniser for your application. Get in touch with us today on +44 (0)1793 511000 to discuss your budget and requirements. We can also offer an ESD Assessment of your area to help determine what types of ESD control equipment is required for your ESD Control Plan. Whether you need an esd mat or contamination control tacky mats, we can help!

Bondline Electronics Ltd are a trusted supplier of ESD control products since 1986, see their full range of static control consumables and ionisers on www.bondline.co.uk

Fields marked with an * are required

On selected products if ordered before 1pm

Dedicated account manager to help your ordering process

Great value on premium quality products

Bondline Electronics Ltd are a leading manufacturer and supplier of static control products within the ESD industry. Products such as Flexible and Rigid Packaging, Bench Matting, Wrist Straps, Heel Grounders and Shoes, ESD Protective Clothing and Gloves, Test and Measurement Equipment along with many storage and handling solutions.

Bondline products are all qualified and compliant according to IEC-61340-5-1 International Standard.

Registered Company Number: 02933918

Office Hours: Mon – Thurs: 9am – 5pm Fri: 9am – 2pm

Bondline Electronics Ltd are a leading manufacturer and supplier of static control products within the ESD industry. Products such as Flexible and Rigid Packaging, Bench Matting, Wrist Straps, Heel Grounders and Shoes, ESD Protective Clothing and Gloves, Test and Measurement Equipment along with many storage and handling solutions.

Some of these cookies are essential, while others help us to improve your experience by providing insights into how the site is being used.

For more information and to read more about our privacy policy, please visit our Privacy Policy

Necessary cookies enable core functionality. The website cannot function properly without these cookies, and can only be disabled by changing your browser preferences.