A Trusted UK Supplier Of ESD Control Products Since 1986

A Trusted UK Supplier Of ESD Control Products Since 1986

ESD Static Control Swabs are engineered to eliminate damage from static electricity – utilizing full ESD safe construction. ESD safe swab applicators are ideal for use in electronic assembly, as a medical device or even for applying solutions or for removing particulates.

Buy now!

Controlling electrostatic discharge (ESD) is an important aspect of ensuring the quality of electrical components throughout manufacturing processes. By nature, some electronics are more sensitive to static than others, which is why many manufacturing plants have special environments like cleanrooms for keeping static at the lowest possible levels. While it’s equally important to protect electronics against ESD after manufacturing, such as throughout transport and device assembly procedures, controlling the levels in critical manufacturing environments is the first step to keeping your components intact.

Swabs are used throughout electronic assembly for a number of different purposes. Your employees might use them to apply adhesives, or cleaning small, hard-to-reach places. They also come in handy for surface sampling and validation procedures in cleanroom environments.

If your employees use swabs during any stage of the workflow while handling electronics, it’s advisable to provide them with anti-static swabs to further eliminate ESD. Anti-static swabs have all of the benefits of traditional swabs, allowing you to clean fragile machinery and small components, but do not carry the risk of transmitting static to your electronics.

These swabs are unique in the fact that they feature special shaft materials which are inherently static-free. For instance, many of these swabs’ shafts contain carbon, which is known to eradicate any static build-up. Common shaft materials for anti-static swabs are static dissipative polypropylene and wood (wood swabs are generally not safe for cleanrooms but could still be used in Electrostatic Discharge Protected Areas or elsewhere.

Ideally, it is best practice to wear ESD gloves that are grounded to Earth via a wrist strap and cord when using antistatic swabs. This will ensure that any static charge is grounded, allowing you and the electronic component/device to be static safe.

Bondline offer a wide range of swabs designed to protect ESD sensitive components from electrostatic discharge and to easily remove particle and residue, with no abrasion. ESD Safe Cleanroom Swabs enable ESD safe swabbing of small static sensitive components where ESD events must be controlled.

Ideal to use in Cleanrooms (microelectronics, etc.) and allows for easy cleaning and removal of particle contaminations and residue.

Bondline’s swab range includes:

Polyester tipped swabs are the cleanest type of swabs available today. They are widely used to clean electronic optical lenses, sophisticated instruments, and other equipment in cleanrooms. Alongside this, they make excellent applicators for easy cleaning and removal of particle contaminations and residue.

Most polyester swabs have a handle made from a patented inherently polymer material. This provides a clean permanent protection without contributing particulate contaminates to the cleanroom. These swabs help to minimise risk of static electricity damage by providing a way for charges to ground.

What are polyester tipped swabs good for?

These types of swabs are great for the following:

When to use polyester tipped swabs?

Polyester tipped swabs are available for many purposes and become the first choice for many users in many industrial applications.

Foam tipped swabs are designed for use in specific environments like precision manufacturing, fiber optics, electronics, semiconductors, printing, aerospace, biotechnology, and pharmaceuticals. They are excellent for easily removing particles and residues with no abrasion. Like the polyester tipped swab, its handle is made from a patented inherently polymer to provide clean permanent protections without contributing particulate contaminates to the cleanroom. These swabs help to minimise risk of static electricity damage by providing a way for charges to ground.

What are foam tipped swabs good for?

These types of swabs are great for the following:

When to use foam tipped swabs?

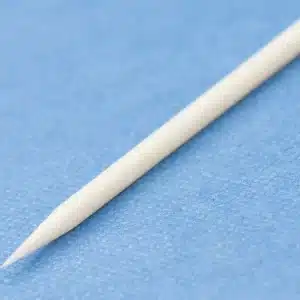

Sharp stick tipped swabs allow for the careful removal of particles and residue from hard-to-get-to areas. These swabs make excellent precision applicators for even the smallest electronic components. They are suitable for use in Cleanroom environments and help to minimise risk of static electricity damage by providing a way for charges to ground.

What are sharp tipped swabs good for?

When to use sharp tipped swabs?

By choosing swabs designed to keep ESD at bay, you can reduce the risk of compromising your sensitive products and potentially costing your organization countless money and time in damages. Bondline is a leading UK supplier and vast stockist of ESD products and consumables. If you would like guidance on choosing the right ESD swab, please contact us and we’d be happy to help!

Can’t find what you are looking for? Please contact one of our expert sales members for more advice.

On selected products if ordered before 1pm

Dedicated account manager to help your ordering process

Great value on premium quality products

Bondline Electronics uses cookies and tracking technologies to analyse our traffic, and for advertising/targeting purposes.

Cookie technology helps us to deliver content tailored to a visitor's interest, improve our site's performance and security, and makes a number of actions easier.

You can read more in our Privacy Policy and find out how to opt out at any time.